As we look toward 2025 and beyond, the logistics industry is undergoing a profound transformation. Advances in artificial intelligence (AI) are playing a pivotal role in reshaping how goods move around the world—making supply chains faster, smarter, and more resilient. The logistics sector, long associated with manual processes and labor-intensive tasks, is now evolving into a technology-driven ecosystem where AI reigns as a force for efficiency and innovation.

But how exactly is AI changing the logistics landscape? In this post, we’ll explore the most significant ways AI is revolutionizing logistics and setting the stage for an industry that will look very different in the coming years.

1. AI-Driven Demand Forecasting

One of the most game-changing applications of AI in logistics is its ability to enhance demand forecasting. Traditional forecasting methods often rely on historical data and general trends. AI, however, goes a step further by using machine learning algorithms to predict demand more accurately, taking into account a wide array of real-time factors—ranging from seasonal fluctuations to market dynamics and external disruptions like natural disasters or geopolitical events.

With AI, logistics companies can anticipate changes in demand much faster and more accurately, allowing them to adjust their supply chain operations accordingly. This results in reduced waste, optimized inventory levels, and a significant decrease in the cost of holding excess stock.

In 2025 and beyond, AI-powered forecasting will continue to refine the supply chain’s ability to meet market demands with unprecedented precision. Companies that invest in this technology will not only improve efficiency but also gain a competitive edge in a rapidly changing market. To fully leverage AI’s potential in logistics, many companies are turning to supply chain consulting experts. Platforms like Toptal provide access to top-tier consultants who help design and implement data-driven, scalable strategies tailored to complex supply chain needs.

2. Robotic Process Automation (RPA) and Autonomous Vehicles

Automation is becoming a cornerstone of logistics, and AI is supercharging it in ways previously unimaginable. Robotic process automation (RPA) has enabled the automation of repetitive tasks like data entry, inventory tracking, and shipping documentation. By reducing human involvement in these tasks, businesses can lower error rates, cut labor costs, and speed up administrative processes.

However, the true AI revolution in logistics will be seen in the deployment of autonomous vehicles. Drones, self-driving trucks, and automated guided vehicles (AGVs) are already making headlines, but their widespread adoption is expected to redefine how goods are transported.

Autonomous trucks, in particular, are poised to address one of the industry’s biggest challenges—a shortage of drivers. AI-powered trucks will be able to navigate complex routes, drive long distances without breaks, and avoid traffic jams with real-time route optimization, all while reducing accidents caused by human error. In fact, logistics companies investing in autonomous delivery vehicles are likely to see a sharp decline in transportation costs and an increase in delivery speed.

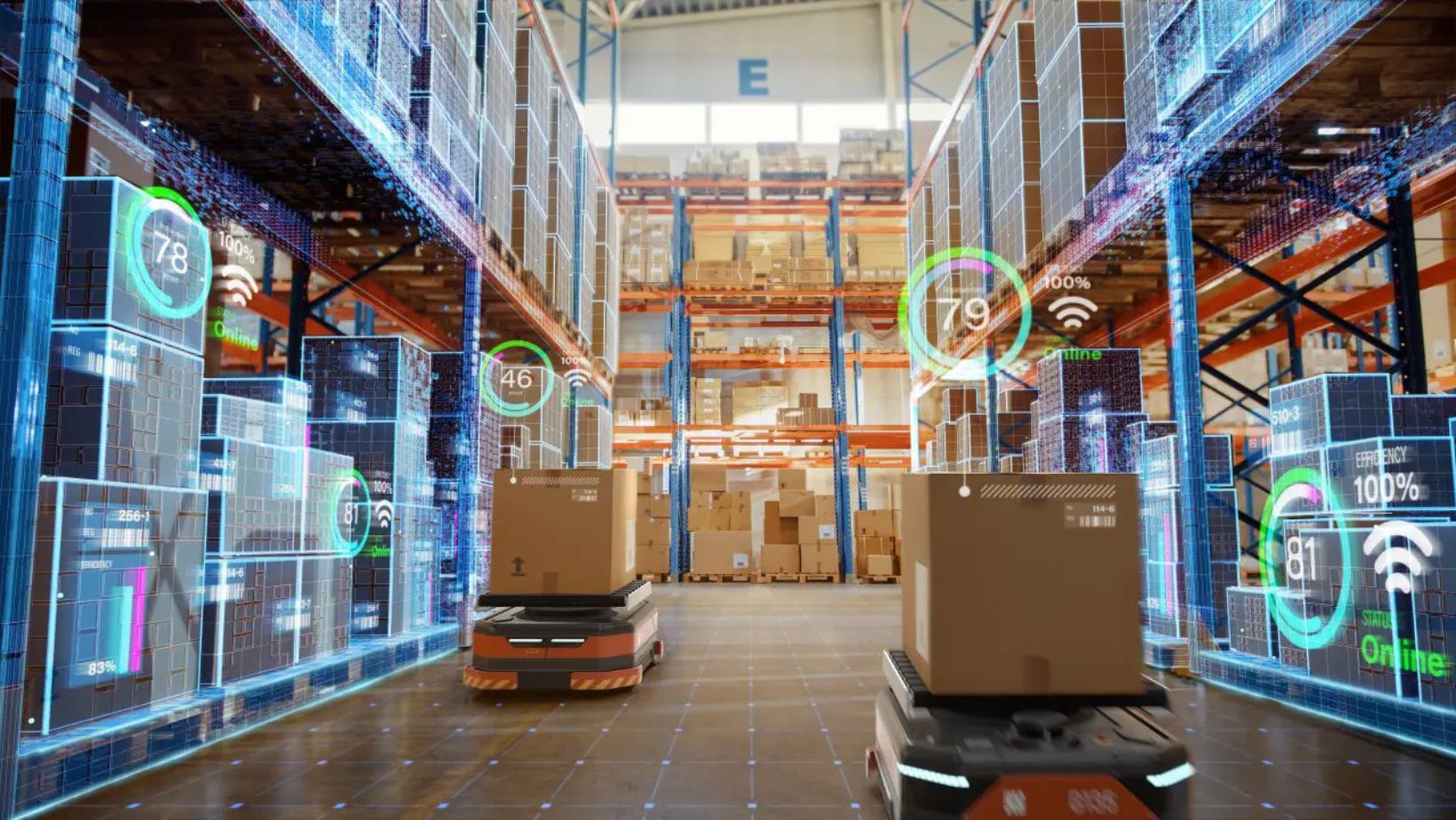

3. Intelligent Warehouse Management

Warehouses have traditionally been hubs of manual labor and paper-based processes, but AI is making these operations much more intelligent and streamlined. AI-driven warehouse management systems (WMS) now allow for real-time tracking of goods, automated picking and packing, and even predictive maintenance of equipment to reduce downtime.

Machine learning algorithms can optimize warehouse layouts by predicting the best places to store items based on factors like product demand, picking frequency, and storage space constraints. This reduces bottlenecks and ensures faster fulfillment, ultimately improving customer satisfaction.

One of the most exciting innovations in this area is the use of AI-powered robots for sorting and picking. These robots can analyze data to decide the most efficient way to retrieve items, saving valuable time and effort. By 2025, we can expect to see even more AI-driven robotics handling the most labor-intensive tasks in warehouses, from heavy lifting to intricate sorting, resulting in a massive productivity boost.

4. Route Optimization and Last-Mile Delivery

Last-mile delivery—the final leg of the supply chain—has always been one of the most challenging and costly aspects of logistics. AI is tackling this problem head-on by offering powerful route optimization solutions.

AI algorithms can analyze traffic patterns, weather conditions, and other real-time factors to find the most efficient delivery routes. This leads to faster deliveries, lower fuel costs, and reduced environmental impact. AI also enhances flexibility in delivery scheduling, allowing companies to offer more precise delivery windows to customers, which improves satisfaction.

Moreover, AI-powered drones and robots are becoming viable solutions for last-mile delivery in urban areas, where traffic congestion and parking limitations pose significant challenges. Companies like Amazon have already started testing drone deliveries, and by 2025, we may see a major shift toward AI-driven autonomous deliveries.

5. Supply Chain Risk Management

Supply chain disruptions have always been a looming threat to logistics operations. Natural disasters, supplier bankruptcies, and even political unrest can wreak havoc on carefully planned supply chains. Traditionally, businesses have had limited ability to predict or mitigate these risks.

AI changes the game by offering advanced risk management solutions. Machine learning algorithms can process vast amounts of data to identify potential supply chain vulnerabilities. Whether it’s a predicted storm in a key shipping region or an impending supplier issue, AI can forecast risks and recommend preemptive actions to mitigate disruptions.

AI can also help businesses diversify their supplier base and automatically reroute shipments when a disruption occurs, ensuring that the supply chain remains functional and minimizing the impact of delays.

6. AI-Enhanced Customer Service with Chatbots

Customer expectations for fast, reliable service are higher than ever, and AI is stepping in to ensure logistics companies meet those expectations. AI-powered chatbots and virtual assistants are increasingly being used to handle customer inquiries, track orders, and resolve issues in real time.

These chatbots are not only capable of processing vast amounts of information quickly, but they are also constantly learning from customer interactions. Over time, they become better at predicting customer needs and offering personalized responses, improving customer experience and reducing the burden on human customer service teams.

In 2025, we can expect AI-powered customer service to become even more sophisticated, handling complex inquiries that previously required human intervention. This shift will allow logistics companies to scale their operations without sacrificing the quality of customer support.

7. Predictive Maintenance for Fleet and Equipment

AI’s predictive capabilities extend far beyond just forecasting demand. In logistics, AI is being used to monitor and maintain vehicles and equipment before breakdowns occur. Predictive maintenance relies on machine learning to analyze data from sensors placed on trucks, drones, forklifts, and other equipment to detect signs of wear and tear.

By identifying potential issues early, companies can service vehicles and machinery before they fail, avoiding costly repairs and minimizing downtime. In a world where supply chains operate 24/7, any downtime can lead to significant delays, making predictive maintenance a key advantage for logistics operations.

Overcoming Barriers to AI Adoption

While the benefits of AI in logistics are clear, there are still barriers to widespread adoption. High initial costs, data integration challenges, and concerns over workforce displacement can create hesitation. However, many of these challenges are being addressed through new AI solutions that are more accessible and adaptable to existing systems.

Moreover, the logistics workforce can evolve alongside AI, with many roles shifting from manual labor to more strategic, tech-oriented positions. Training programs and upskilling initiatives, as outlined in a Comprehensive Call Center Training Guide, can help workers transition to these new roles, ensuring that AI is seen as an enabler, not a threat.

In the coming years, we can expect AI solutions to become even more sophisticated and user-friendly, making it easier for companies of all sizes to adopt these technologies. This will lead to a more connected, agile, and efficient logistics industry where AI becomes the standard rather than the exception.

The Future of AI in Logistics: What Lies Ahead?

Looking ahead to 2025 and beyond, the role of AI in logistics will only grow stronger. We will likely see even more advanced applications of AI, such as:

- AI-enhanced supply chain control towers that offer real-time, end-to-end visibility across global operations.

- Hyper-personalized delivery services driven by AI-powered insights into customer preferences and behaviors.

- Seamless integration of AI with other emerging technologies, such as blockchain, 5G, and the Internet of Things (IoT), creating fully automated, data-driven logistics ecosystems.

These innovations will redefine the boundaries of what’s possible in logistics, making supply chains faster, more flexible, and more responsive than ever before.

Conclusion

The logistics industry is on the brink of a transformation, driven by AI technologies that are reshaping how goods are transported, stored, and delivered. From AI-driven demand forecasting and autonomous vehicles to intelligent warehouse management and last-mile delivery optimization, AI is revolutionizing the way logistics companies operate.

While there are still hurdles to overcome, the future of logistics is undeniably AI-driven. By investing in these technologies now, logistics companies can position themselves at the forefront of innovation, improve efficiency, and provide exceptional customer experiences.

As we approach 2025 and beyond, one thing is certain: AI will continue to revolutionize logistics, making supply chains more resilient, cost-effective, and sustainable. The companies that embrace AI today will not only meet the challenges of tomorrow but will also shape the future of the logistics industry.